Getting the Desired Shape of Your Metal Sheet

No matter which industry you take, if there is production of some heavy products or something in bulk, machines are involved in large numbers. This is because all the major work is done them. Gone are the times when there used to be manual labor present in large numbers just to do one work. Humans have been over shadowed by machines which helped the industry in increasing their productivity. Not only there are less people involved, but the whole procedure takes very less time to get completed. Overall, we have let machines take control of our lives for the betterment. The same is also true in electrical work. Whichever electrical industry you take place, you are surrounded by machines. Plate bending machine is one of those machines that is used in our life to simplify our work.

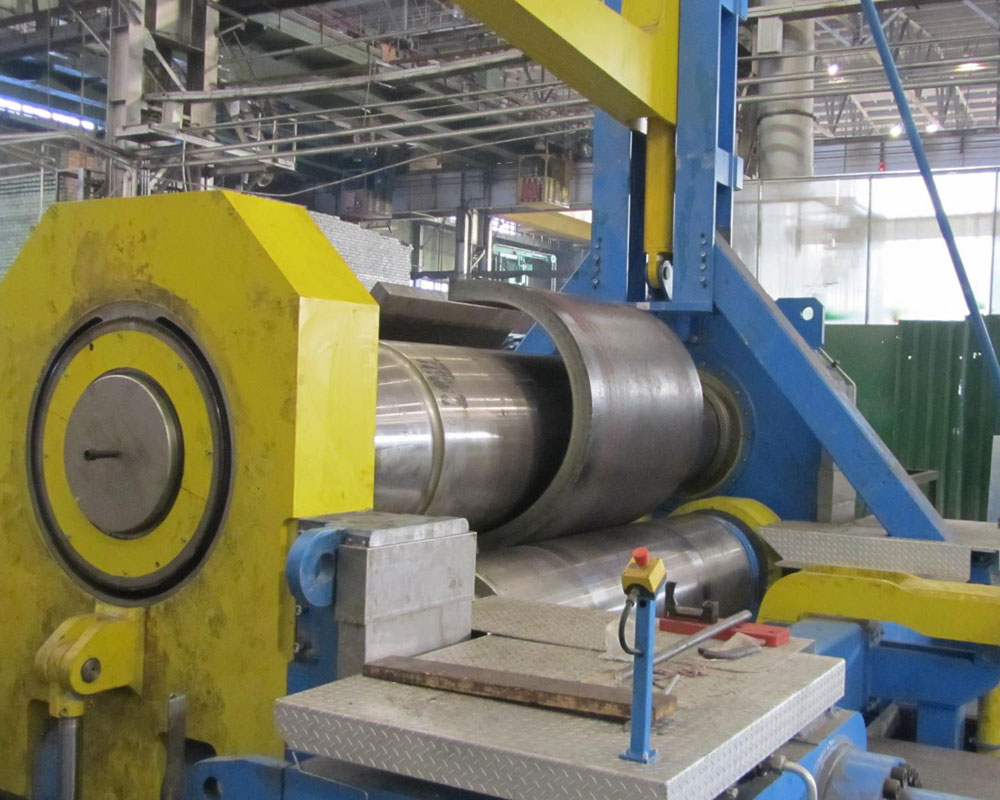

A plate bending machine is needed when there is need of changing the shape of sheet metal. By the use of plate bending machines, a metal sheet is rolled in different shapes such as round, conical etc. There are different names given to a plate bending machine such as roll bending machine, rolling machine etc. there are various different reason why a plate bending machine is preferred. Some of its advantages are –

1. They have high efficiency.

2. The performance of the machine is very smooth.

3. It has low maintenance cost.

4. The functioning of this machine is very reliable.

5. High working capacity is one more of their advantage.

While working on a plate rolling machine, there are different technology based depending on the components. There are three roller and four roller machines. In a four roller machine, there are two side rolls present along with a top roll and a pinching roll. The work of bending is done with the help of side rolls and the pinching roll holds the plate. In a three roller machine, there is one pressing top roll and two pressing side rolls. The top roll moves in vertical plane and the side rolls moves in horizontal plane.

Tags :plate rolling machine, n. s. energy groups, plate bending machine, roll bending machine, four roller machines, two pressing side rolls,