Suppliers of Heavy Machinery in Every Field

If there is one thing for which we should be thankful to, in terms of advancement, is technology. We have come a long way from earlier times, when there was nothing to make human work easier. We used to do all our own work and almost all of our time used to consume in doing one particular work. Lot of manpower was required in doing even a small quantity of work. In fact, there were no machines at all and nobody would have thought that a thing which used to take up whole day was possible in just minutes. But all of this has changed now. This is the power of technology. We don’t have to worry about any of that now. No matter how big the work is, we are not bogged down by any of it. Machines help in smooth transition in the whole process. No matter what industry there is, you cannot imagine any work without them. You can say that we have become dependent on them. Just like every field, we have use of machines in turbines also.

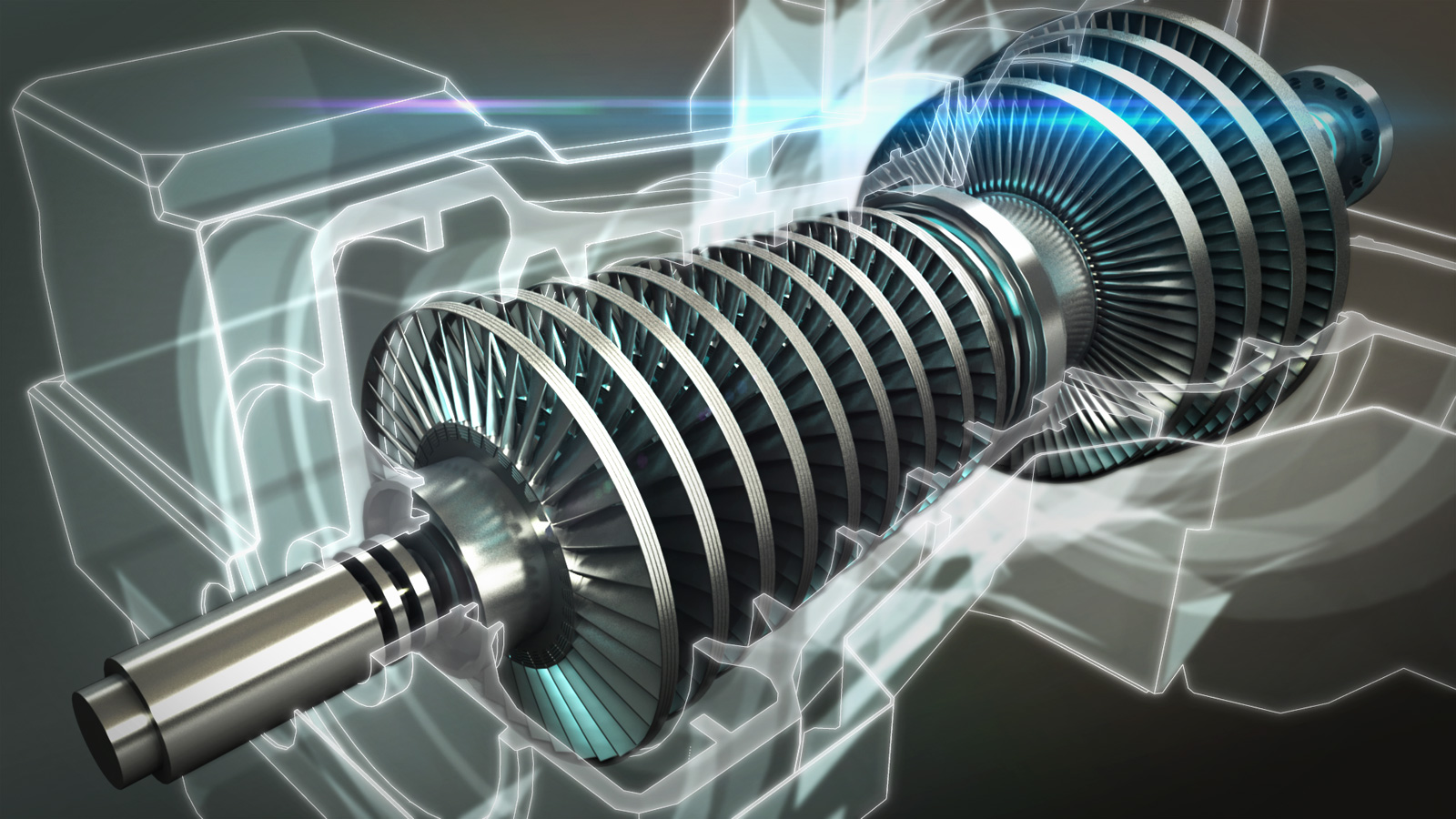

The main use of a turbine is to extract energy from water and convert it into work. Water is a very good source to use in production of energy. It is because water is a renewable source of energy and does not cause harm to the nature. It is not a source of pollution, hence it is used by many industries. When we specifically talk about a steam turbine, it uses thermal energy to do mechanical work. This work is done on a rotating shaft. The efficiency is increased because we use multiple stages in the expansion of the steam which helps is ideal reversible expansion process. A steam turbine is largely used because they have various advantages. Some of them are given below –

1. It is best suited to drive an electrical generator because of the presence of the rotary heat engine.

2. If we require high power output on a regular level, then steam turbines are the best option.

3. Steam turbines have very less vibrations because they move only in one direction.

4. Due to the presence of high amount of enthalpy, they have lower mass flow rates when compared to a gas turbine.

5. They have greater efficiency when compared with a reciprocating engine.

6. They have high power-to-weight ratio.

7. Steam turbines have higher reliability.

8. If you have large thermal power plants, then steam turbine is the best option.

A steam turbine has different components. It is necessary for all of them to work in an efficient manner. Some of the common parts are – steam pipeline, inlet control valve, nozzle chamber, nozzle box, outlet, stator, blade carrier, casing, rotor disc, rotor, journal bearing, thrust bearing, generator rotor, coupling, labyrinth packing, steam bleeding, bearing pedestal, safety governor, main oil pump, centrifugal governor, main oil pump, turning gear, control stage impulse blading etc.

A steam turbine also has high speed gear boxes, spare parts and different types of turbines. Some of them are explained below –

1. Single Stage Steam Turbine – they can work on a temperature of about 538 degree Celsius. Maintenance is not an issue and they have longer working life. They have customized steam path components along with mechanical safety trip system. You can have electronic and hydro mechanical governors in it. They have use in oil and gas, food processing, chemical processing, pharmaceutical, steel, paper, sugar, palm oil, marine industries.

2. Multi Stage Steam Turbine – a multi stage steam turbine is given this name because it has more than one rotor discs that are mounted on the shaft. They have inlet pressure of up to 105 bar and inlet temperature of up to 560 oc. Their design is compact and has flawless performance. They have use where there is power generation.

3. Back Pressure Steam Turbine – in these turbines, the steam that we receive from the exhaust is not condensed back into water and is used for some other process. They are used in those industrial processes where there is need of low to medium pressure steam. They are used in drive applications.

Tags :steam turbine, high speed gear boxes, single stage steam turbine, multi stage steam turbine, back pressure steam turbine, n. s. energy groups